Heat exchange units play a significant role in multiple industries, serving as devices that facilitate the exchange of thermal energy between multiple or more gases without mixing them. Grasping what a heat exchanger is and how it works is essential for individuals involved in design, manufacturing, or processes that rely on thermal management. From maintaining energy efficiency in HVAC systems to enhancing functions in power plants, the demand for efficient thermal management approaches has reached an all-time high.

As with every mechanical system, heat exchangers can experience common issues that may hinder performance and efficiency. Knowing how to troubleshoot these problems can conserve time, materials, and expensive repairs. In this article, we will investigate the various types of heat exchangers, essential applications across industries, and the importance of regular maintenance. We will also cover new designs and substances that are transforming the future of heat exchanger technology, ensuring that these essential components adapt to the evolving demands of modern applications.

Comprehending Heat Exchange Systems

Heat exchange devices constitute crucial devices employed across different industries for exchanging thermal energy among a pair of or more fluids while not blending them. Their primary role is to optimize heat conduction, that helps in boosting system effectiveness. By facilitating the elimination and intake of thermal energy from a single fluid to a different one, heat exchangers play a crucial role in uses ranging from industrial processes to residential warmth and refrigeration systems.

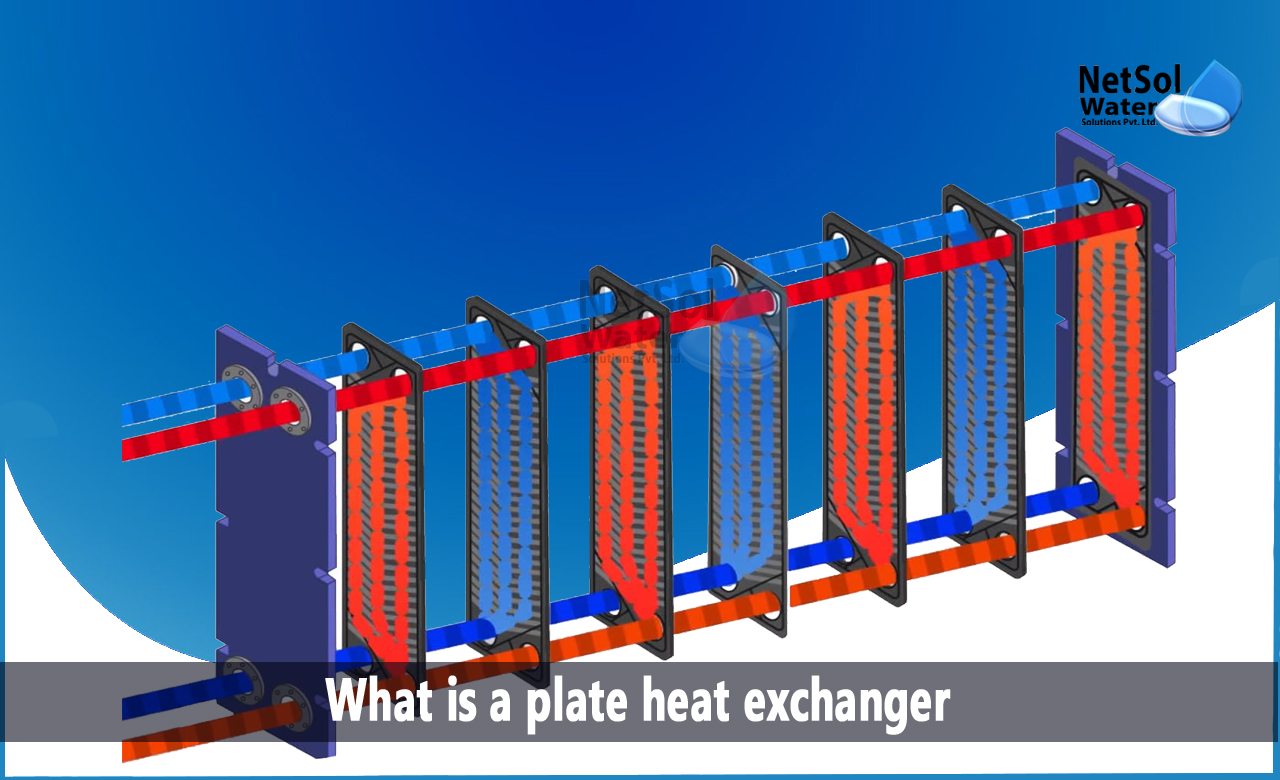

Numerous different types of heat exchangers, each specifically designed to fulfill distinct functions and applications. Common types include shell and tube, plate-type, air-cooled models, and finned-tube heat exchangers. Each type possesses distinct advantages and drawbacks regarding heat transfer efficiency, spatial needs, and ease of maintenance. Understanding the different configurations enables engineers and operators to choose the ideal heat exchanger for their particular needs, thus ensuring optimal performance and efficiency savings.

The performance of a heat exchanger is influenced by multiple factors, including the thermal gradient among the fluids, flow arrangement, and the material employed in its construction. Monitoring these parameters is essential for maintaining effectiveness and prevents issues such as clogging, which can significantly reduce a unit's efficiency. By comprehending the fundamental principles of heat exchangers, involved parties can more effectively troubleshoot problems, optimize system design, and enhance the longevity of their machinery.

Uses and Performance

Heat exchange systems play a critical role in multiple industries, illustrating their adaptability and significance in energy transfer processes. In HVAC systems, they are essential for regulating temperature and enhancing air quality, permitting buildings to keep comfortable environments while streamlining energy use. In power plants, heat exchangers assist heat transfer from combustion processes, securing efficient energy generation and minimizing emissions. Additionally, sectors like the food industry and beverage processing utilize heat exchangers for pasteurization and cooling, which are essential for ensuring product quality and safety.

The effectiveness of heat exchangers significantly affects overall energy consumption in industrial operations. For case in point, using heat exchangers in combination with green energy sources leads to lower operational costs and increased sustainability. They allow for the recovery of heat, diminishing the need for additional energy inputs. Comprehending heat transfer efficiency in these devices is crucial; factors such as design, material selection, and maintenance practices directly affect performance.

In recent years, advancements in heat exchanger technology have additionally improved efficiency and adaptability. Small designs, advanced materials, and digital monitoring systems have emerged, allowing industries to meet unique operational needs while reducing energy waste. The incorporation of smart technologies allows predictive maintenance, securing that heat exchangers operate at optimal efficiency and extending their lifespan. By adopting these advancements, organizations can achieve substantial energy savings and continue their dedication to sustainability.

Typical Challenges and Remedies

Heat exchangers can experience various issues that impact their efficiency. One frequent problem is contamination, where deposits accumulate on heat transfer surfaces, diminishing heat transfer efficiency. To mitigate this problem, regular maintenance routines should be set up, using techniques such as chemical cleaning or brushing. Keeping track of the pressure drop across the heat exchanger can help detect fouling early, allowing for timely maintenance and reducing downtime.

Another common problem is leaks, which can occur in seals, fusion points, or other connections. These leaks not only compromise the operational efficiency but can also cause hazardous situations if fluids are involved. To manage leaks, performing routine inspections is essential. When leaks are detected, immediate remedies or upgrades should be executed, and the integrity of the whole unit should be evaluated to prevent future events.

Issues with temperature regulation can also affect heat exchangers, resulting in inefficient operation or overheating. engineering plans for hot water loop can be caused by malfunctioning thermostats, inaccurate flow rates, or complications with the surrounding systems. To solve these issues, ensure proper tuning of temperature control devices and consider automating monitoring processes for real-time detection of deviations. Adjusting flow rates and executing regular system audits can aid in maintaining optimal temperature control within the heat exchanger.