Heat exchange systems are key components in a variety of industries, playing a critical role in the transfer of heat between several fluids. These devices make it viable to efficiently exchange thermal energy, enhancing processes in uses as diverse as HVAC systems, energy generation facilities, renewable energy solutions, and food processing. Understanding how heat exchangers function and the various types available can substantially impact energy performance and operational costs in any manufacturing setting.

In this write-up, we will investigate the fundamental concepts of heat exchangers, review the different types and their specific applications, and highlight the benefits they offer to modern technology. From the differences between shell and tube versus plate heat exchangers to the value of maintenance and developments in design, we aim to provide a thoroughly detailed overview. Whether StandardXchange are a seasoned engineer or a novice to the field, this guide will enhance your understanding of heat exchangers and their essential role in sustainable practices.

Types of Heat Exchangers

Heat exchangers are classified into various types based on their construction and operational principles. The primary categories are active and passive heat exchangers. Dynamic heat exchangers utilize external energy sources to enhance heat transfer, while static types rely on natural circulation or conduction for transferring heat between liquids. Among these, the most utilized designs include shell and tube, plate, finned tube, and air-cooled heat exchangers, each suited for different uses and efficiencies.

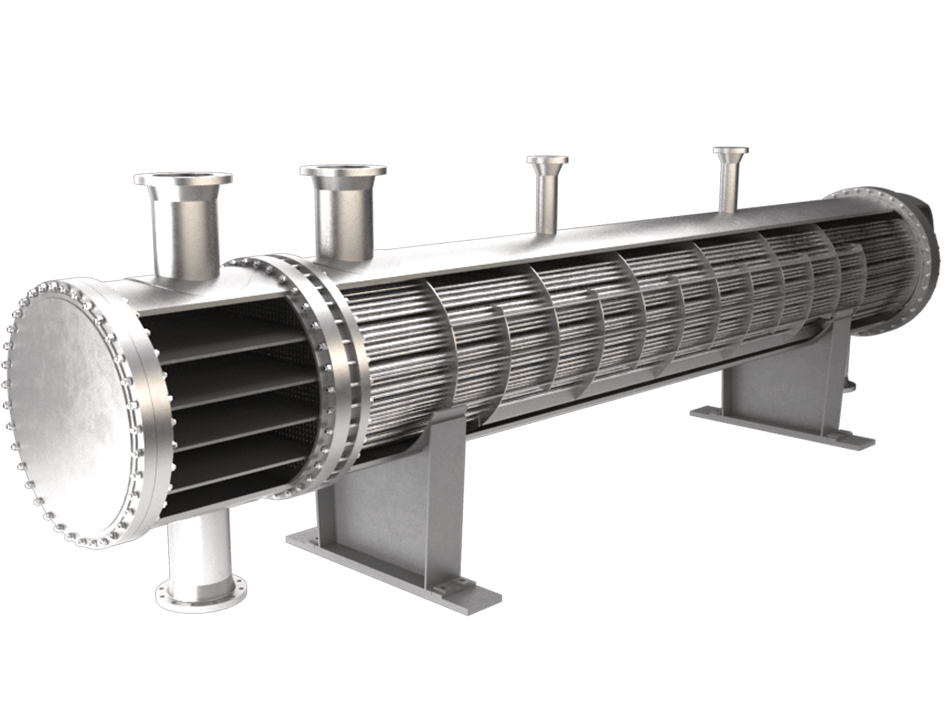

Tube and shell heat exchangers consist of a series of tubes, where one fluid flows through the inside tubes and another fluid flows around them within a shell. This design allows for high heat transfer efficiency and is widely used in sectors requiring strong and long-lasting equipment, such as refining petroleum and power generation. Flat plate heat exchangers, on the contrary, have a array of thin plates that create several channels for fluid flow, promoting increased surface area contact and efficient heat transfer, making them well-suited for food processing and HVAC applications.

A further notable type is the finned pipe heat exchanger, which includes fins to increase the surface area for heat transfer, making them effective in situations where room is limited. Air cooled heat exchangers, utilizing air to cool the fluid, are often used in applications such as refrigeration and process cooling. Each of these heat exchanger types plays a important role in different industries, tailored to meet specific functionally demands and energy-saving goals.

Applications in Fields

Thermal exchangers play a crucial role in diverse industrial uses, contributing greatly to operational efficiency and energy savings. In the chemical sector, for instance of this, these systems facilitate the transfer of heat between multiple process flows, aiding in process reactions and maintaining ideal temperatures. Specifically, they help regulate thermal energy in reactors, separation columns, and other critical machinery, ensuring that processes run efficiently and without risk.

In energy facilities, heat exchangers are essential for the conversion of energy. They assist in conducting heat from burning gases to liquid water, generating steam that operates turbines for the production of electricity. Additionally, these systems help regulate thermal levels across the infrastructure, preventing excess heat and enhancing overall effectiveness. Their design varies between coal-fired plants, natural gas plants, and nuclear power plants, but their fundamental purpose remains the unchanged: enhancing efficiency of energy conversion while maintaining secure operations.

The food and beverage processing industry also is highly dependent on heat exchangers for thermal processing, chilling, and storage operations. These exchangers ensure that products are heated and cooled efficiently to meet safety standards without compromising product quality. By maintaining strict temperature management, they help prolong shelf life and maintain the freshness of products, demonstrating the versatility and necessity of heat exchangers across various industrial sectors.

Maintenance and Effectiveness

Appropriate maintenance of thermal exchangers is crucial for ensuring optimal performance and efficiency. Routine inspections and maintenance help avoid fouling, which can significantly reduce heat transfer effectiveness. Consistently scheduled maintenance protocols should entail the assessment of seals, gaskets, and overall structural integrity to detect any potential areas of failure early. Implementing a systematic strategy to upkeep not only extends the duration of the equipment but also reduces unexpected downtimes and costly repairs.

In terms of efficiency, well-maintained thermal exchangers contribute to energy savings across various systems. By making sure thermal exchangers operate at peak performance, organizations can lower their energy consumption and operational costs. For example, clean heat exchange surfaces encourage better thermal conductivity, which means that less energy is wasted in the heating or cooling processes. This energy conservation is particularly valuable in industries where energy costs make up a substantial portion of business budgets.

At the end of the day, the link between upkeep and effectiveness is obvious; proper maintenance leads to reliable performance. By adopting strategies for preventive upkeep, facilities can enhance heat exchanger reliability while simultaneously achieving sustainability goals. Such foresight in care and management not only improves the function of the thermal exchangers themselves but also strengthens the eco-friendliness of the whole industrial operation.